Services

At SenTherm, we combine advanced Polymer Engineering with expert Design for Manufacture to deliver tailored, high-performance solutions.

Our team specialises in developing customised polymer formulations for a variety of polymer processing techniques, ensuring each material is optimised for its intended application.

With our deep expertise in product and tooling design, we provide seamless, scalable solutions that meet the unique needs of our customers, from concept to production. This integrated approach ensures the highest levels of efficiency, innovation, and quality across the automotive, energy, and industrial sectors.

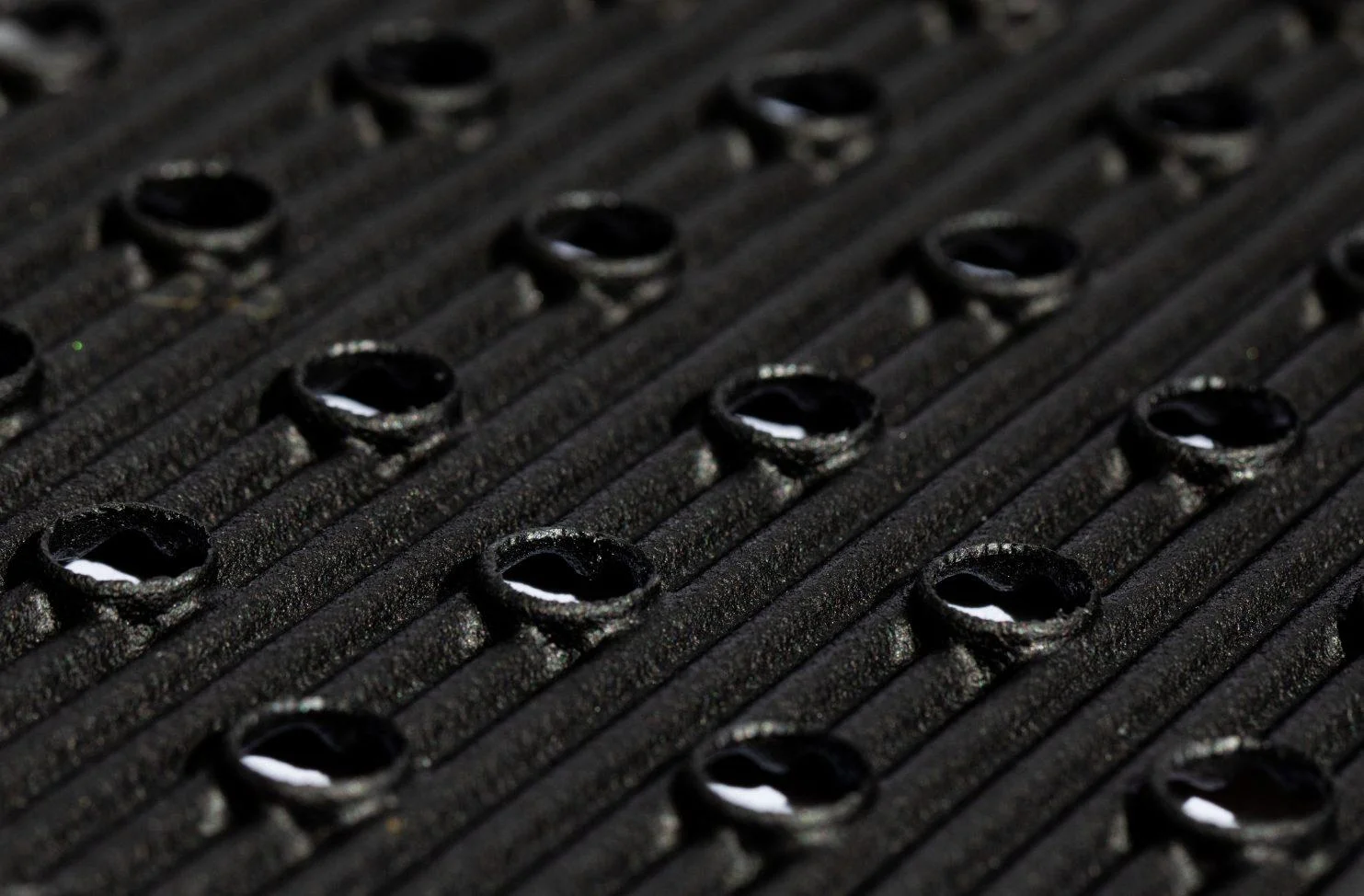

Polymer Engineering

Our expert team leverages core intellectual property and specialised knowledge to develop customised, innovative formulations for injection moulding, thermoforming, profile extrusion and compression moulding.

We deliver tailored solutions that offer:

- High thermal conductivity

- Electrical isolation

- Fire retardancy

- Enhanced processing efficiency

- Optimised additive replacements

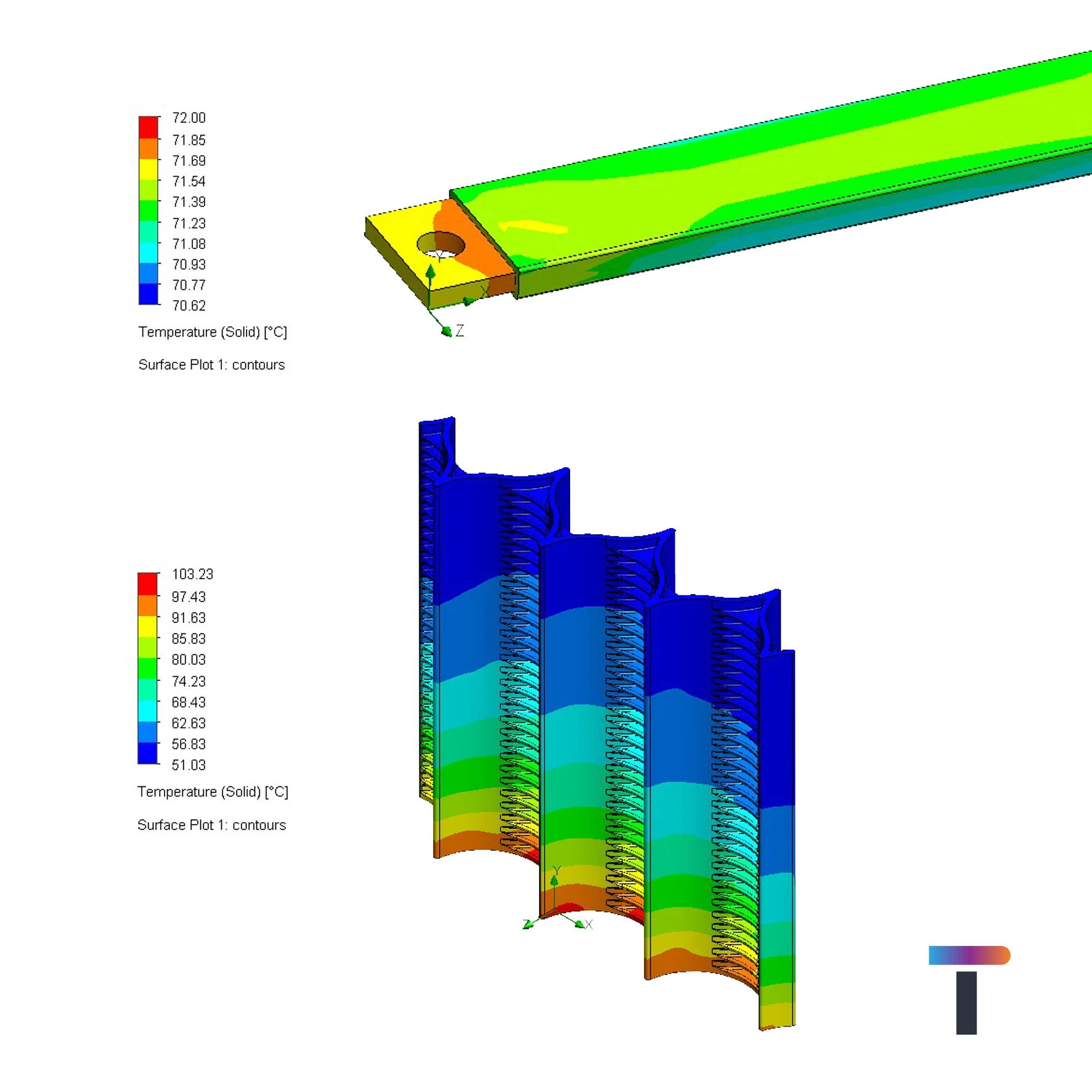

Design for Manufacture

Our knowledgeable team undertake detailed product and tooling design to deliver the optimal solution for our customers.

- Design specification

- Concept and prototyping

- Integration of multiple component parts

- Product design, 3D CAD

- Product heat transfer optimization

- Simulation - CFD, FEA, Moldflow

- Design for assembly

- Tool design and delivery

- Full project management

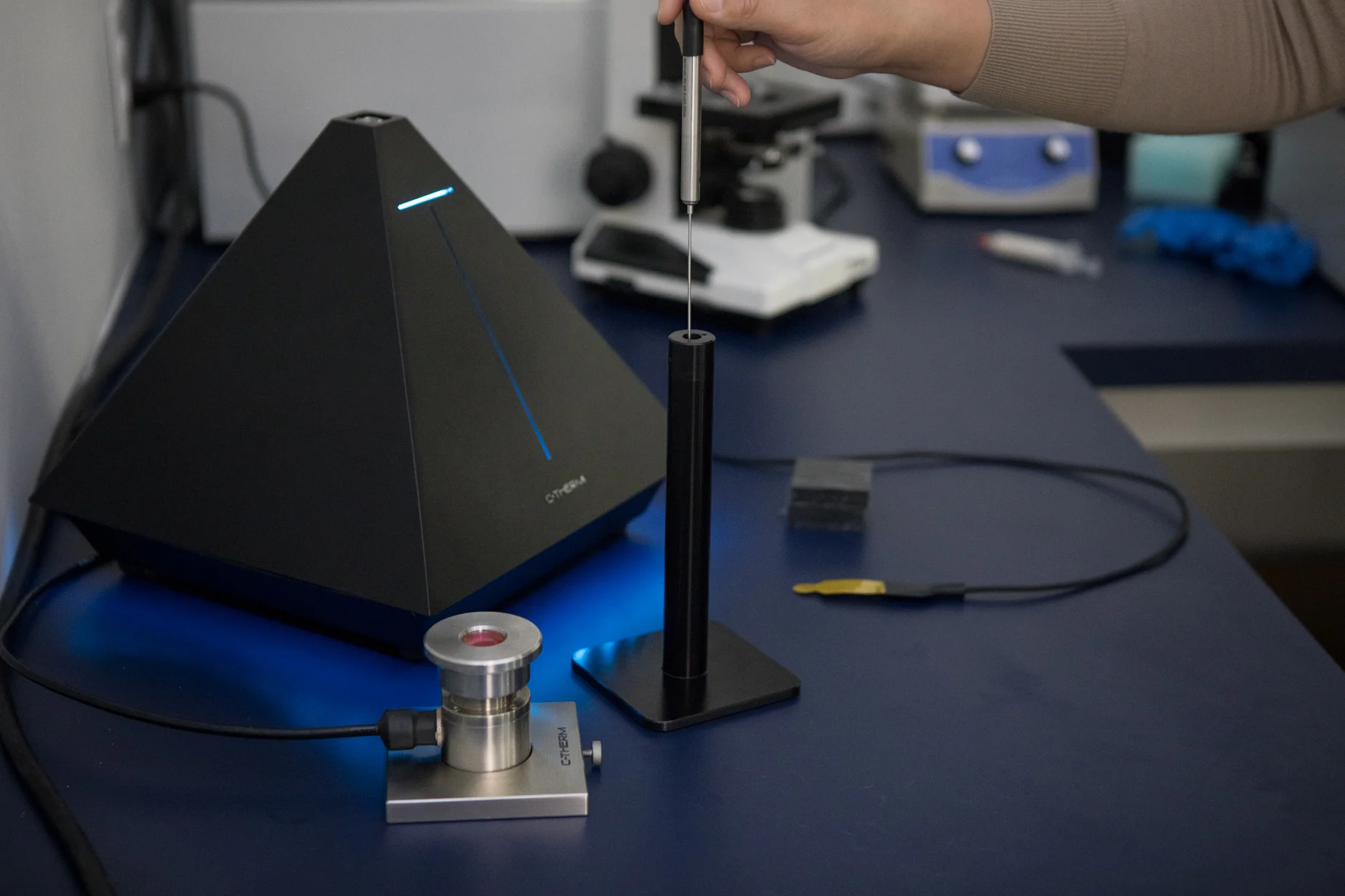

Performance Evaluation

SenTherm provides direct access to a comprehensive suite of advanced evaluation and testing capabilities delivered by an expert team. We assess physical, mechanical, thermal, and electrical properties to evaluate the performance, reliability, and durability of materials, components, and complete systems. This capability reinforces our polymer engineering and design for manufacture expertise, ensuring solutions are fully validated for real-world application.

Image courtesy of C-Therm Technologies Ltd.

Meet the Team

The SenTherm team brings specialist expertise in polymers, underpinning the development and delivery of advanced thermally conductive materials for automotive, energy and industrial systems.

Supported by many years of industry experience across multiple sectors, we combine technical knowledge with practical insight to ensure every solution delivers to the highest standards, while driving efficiency, durability, and sustainability. Working closely with our customers, we collaborate to understand challenges and develop practical solutions that deliver real value.

Previously company owner in commercial roofing, co-founder of Women in Business NI.

Previously director at Comeragh Composites specialising in polymer composites consulting.

Previously Technical & Innovation Director for infrastructure products at CRH and Kingspan.

Leading development of SenTherm's next-gen thermally conductive polymers. Previously polymer compounding at Colorite-Europe and developed conductive polymers at QUB.

Industrial product designer specialising in new product development. Previously CRH, Ward Automation & The Design Factor.

Extensive experience in sales and marketing of renewable technologies. Previously led teams across a range of construction, mining and civil engineering projects.

Specialising in creating value from data. Previous experience in solar thermal, photovoltaic and grid distribution management.